Rope is everywhere, from hoodie drawstrings to shoelaces and decorative ribbons. Made by high-speed braiding machines, they come in various colors and are known for their strength. But have you ever noticed that some braided ropes are smooth and tight, while others are twisted and uneven?

Many people assume it’s a machine malfunction or a production error. However, the real reason is often a clever and intentional manufacturing principle. An experienced craftsman would explain that it’s actually because braiding machines often use two different colored spools of yarn. The direction in which the yarn is wound onto these spools is deliberately opposite for each colour. If all yarn was wound in the same direction, it would cause the finished rope to be uneven.

This “one forward, one reverse” concept is key to producing high-quality braided rope. Let’s explore this industrial wisdom in more detail.

Understanding the Players:

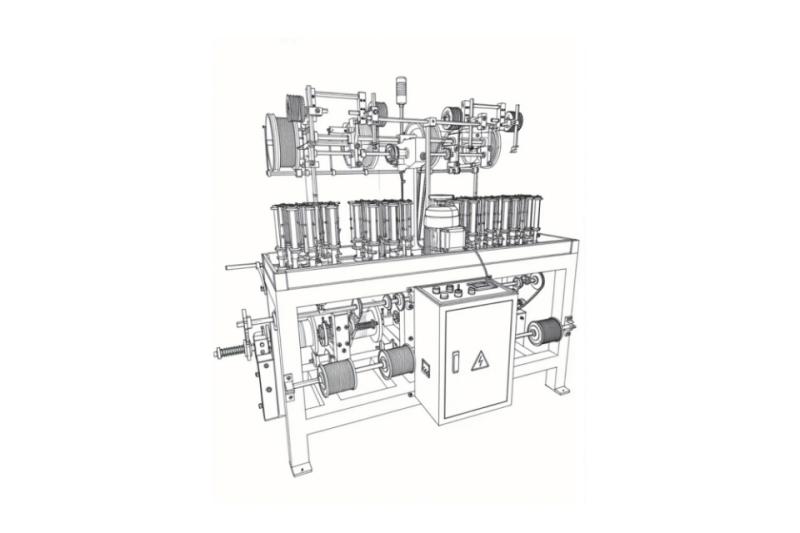

Braiding Machine

Imagine lots of little “knights” (yarn spools) riding “horses” (spindles) moving on a figure 8 or snake-shaped track. The yarn from the spools interlocks and weaves together, forming a rope in the centre.

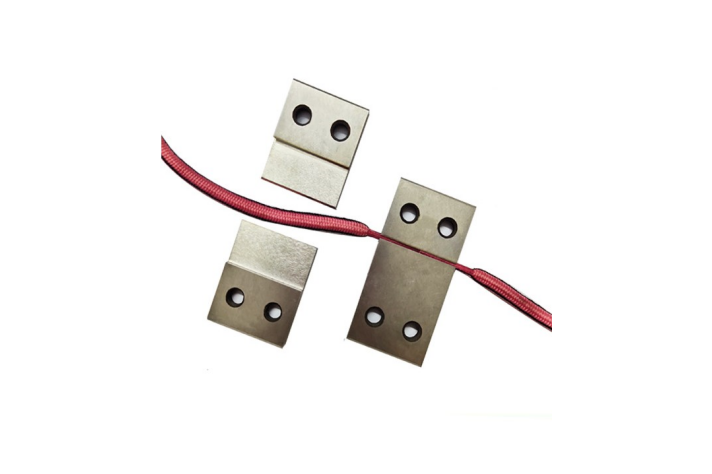

Yarn

Yarn is made of individual fibres twisted together. This “twist” makes the yarn stronger. This “twist” has a direction; think of twisting a braid to make it stronger.

S-Twist (Left Twist)

The twist appears to follow the middle of the letter “S”.

Z-Twist (Right Twist)

The twist appears to follow the middle of the letter “Z.”

Each yarn has a built-in “twisting force” or internal tension due to its twist. Like a wound-up rubber band, it constantly wants to unwind. This, albeit trivial, causes the end problems.

The Root of the Problem:

Why does winding all yarn in the same direction cause problems?

Stress Cancellation

The leftward twisting force of the S-twist yarn cancels the rightward force of the Z-twist yarn.

Structure Stability

The balanced tension eliminates the force that would twist the rope. Therefore, the rope stays straight and in order.

Excellent Quality

A balanced internal structure makes the rope smoother, tighter, and gives the finished rope a more pleasing form

This principle of balance through opposing forces is seen in many forms of engineering, such as sky scrapers.

Conclusion:

Next time you pick up a braided rope, look closely. If it’s straight, smooth, and has a clean pattern, then the “twist balance” technique was likely used. It is the result of textile engineers using all the laws of motion.

This often overlooked detail is the difference between a substandard product and a top-shelf one.

What other challenges have you encountered while using braiding machines? Please share them!