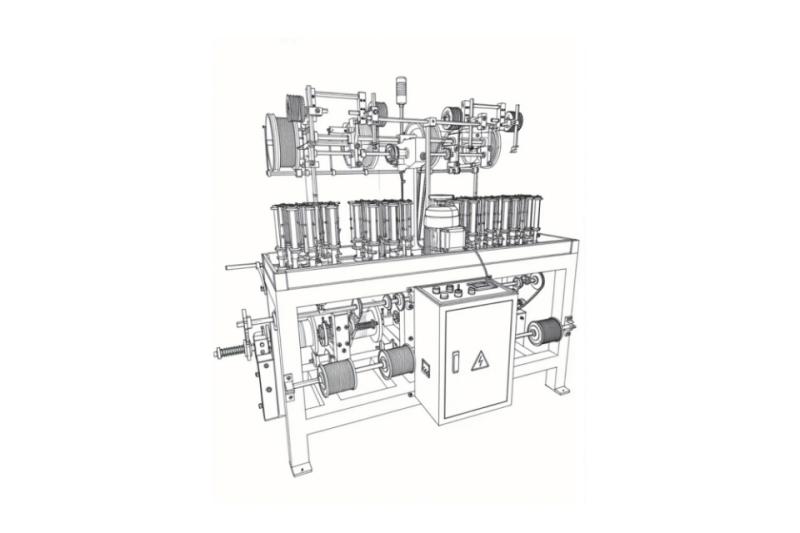

Facing these 6 common issues with your tipping machine? Don’t worry, we have solutions.

1. Film Splits After Wrapping:

- Problem: The acetate film cracks or bursts after being wrapped around the cord.

- Solutions:

- A. Check the Front Cutting Mold (Long Blade Holder): Make sure the screws on the top of the front cutting mold are tightened correctly. They should be snug, not too loose or too tight.

- B. Adjust the Hollow Screw: The hollow screw must also be adjusted correctly. If it’s too loose, the film clip won’t hold firmly. If it’s too tight, the back of the film joint will crack.

2. Cord Won’t Cut:

- Problem: The machine fails to cut the cord cleanly.

- Solution:

- Check Blade Alignment: Ensure the front and back blades are perfectly level. The cord is cut by the friction of the two blades. If the blades are uneven, with dips or bumps, the cord won’t cut properly.

3. Film Folds Before Wrapping:

- Problem: The film folds or bends before it fully wraps around the cord.

- Solution:

- Check the Bottom Cutting Mold’s Triangular Groove: The back blade should retract just past the triangular groove, no more and no less. This ensures the film inserts correctly into the groove and stops.

4. Uneven Tipped Ends:

- Problem: The two sides of the tipped cord end are different lengths.

- Solution:

- Adjust the Film Feed Box: Make left or right adjustments to the film feed box to ensure the film is cut in the center.

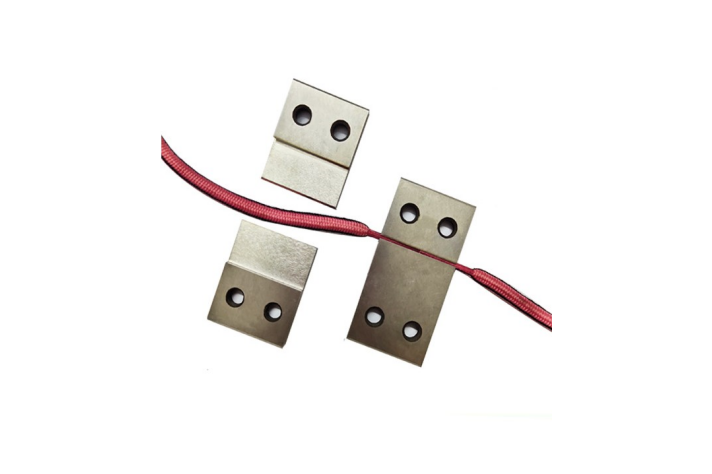

5. Bottom Cutting Mold Sizes:

- Problem: Using the wrong size cutting mold for your blade.

- Solution:

- Choose the Right Mold: The standard mold length is 14mm, suitable for blades 4.0mm and smaller. For blades larger than 4.0mm, use 16mm, 18mm, or 20mm molds.

- Important: The film feed length must not exceed the mold length, or excess film will remain on the back blade.

6. Adjusting Clutch and Brake:

- Problem: Issues with film feed length consistency or clutch pedal feel.

- Solutions:

- Clutch Adjustment: The clutch set screw should be roughly level with the oil hole. (Refer to the provided picture.)

- Brake Adjustment: If the clutch screw is above the oil hole, the brake is too loose, and the clutch pedal will feel heavy. Tighten the brake.

- Film Feed Brake: If the film feed length varies, slightly tighten the film feed brake screw. (Refer to the provided picture.)

In conclusion, semi-automatic tipping machines are easy to use and maintain, perfect for startups and small workshops. With this troubleshooting guide, you should be able to solve most common issues. Remember, regular maintenance and correct operation ensure long-term stability. If you encounter any other problems or need further technical support, please feel free to contact us. Our professional team is ready to assist you and ensure your production runs smoothly.

For any questions or needs regarding heading machines, feel free to share them with us. It’s always beneficial to have another avenue for problem-solving.