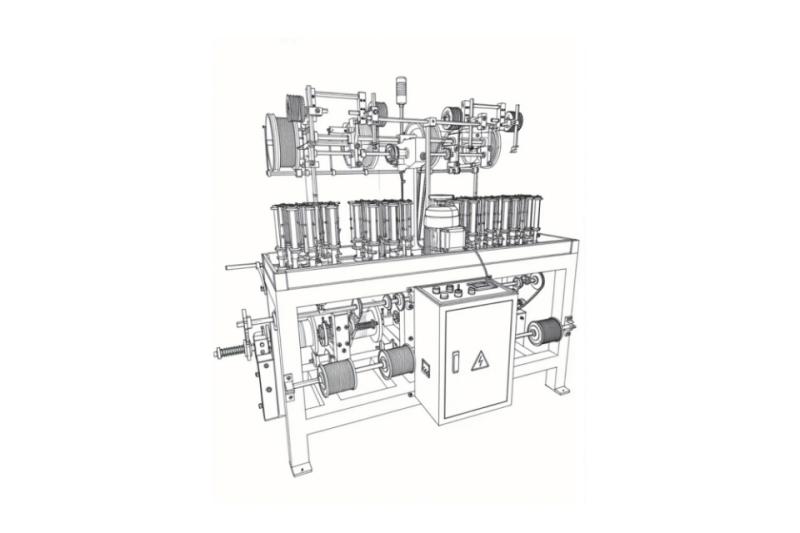

Skipped stitches are a common issue in rope knitting machine operation, resulting in broken or unsightly ropes. This article outlines a 3-step approach to resolving skipped stitch issues and restoring smooth knitting. While the specific appearance of different machines may vary, the underlying principles and troubleshooting techniques remain consistent.

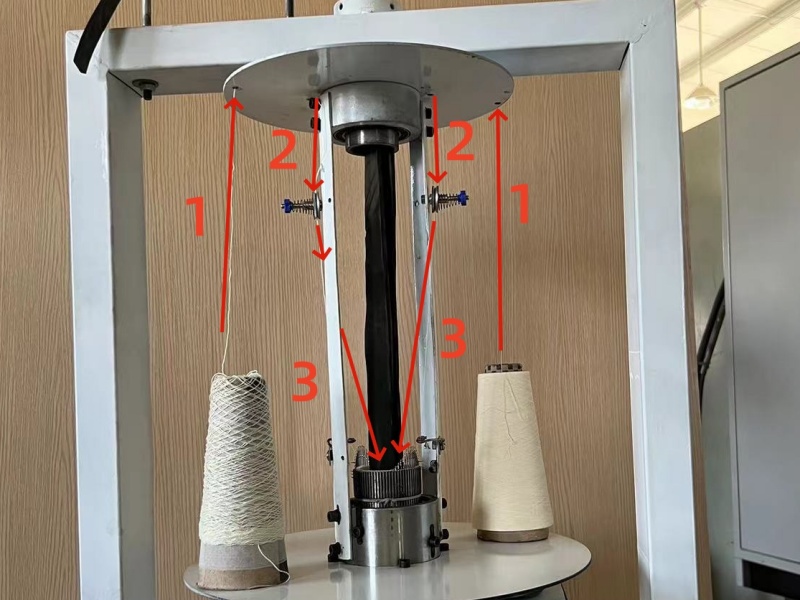

Step 1: Ensure Uniform Yarn Tension

Yarn tension refers to the pulling force exerted on the yarn during the knitting process. Uneven tension can cause the yarn to experience inconsistent pulling forces as it passes through the yarn guides and needles, leading to skipped stitches. Don’t worry, it’s an easy fix.

Inspection Steps:

Observe the yarn path from the spool to its entry into the machine’s interior.

Gently tug on the yarn to check for consistent tension along the path.

If you detect uneven tension, adjust the position of the spool holder, yarn guides, or other related components to maintain uniform yarn tension.

Precautions:

While inspecting, pay attention to the yarn’s tautness, avoiding excessive stretching.

If you notice knots or breaks in the yarn, promptly repair or replace the yarn.

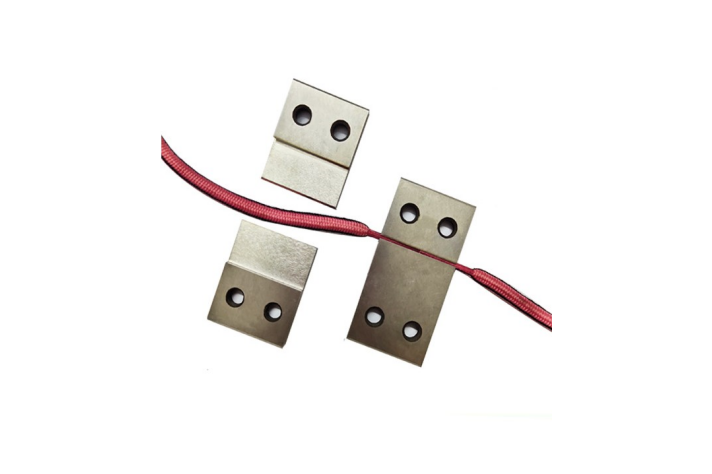

Step 2: Inspect Yarn Tension Controller and Needles

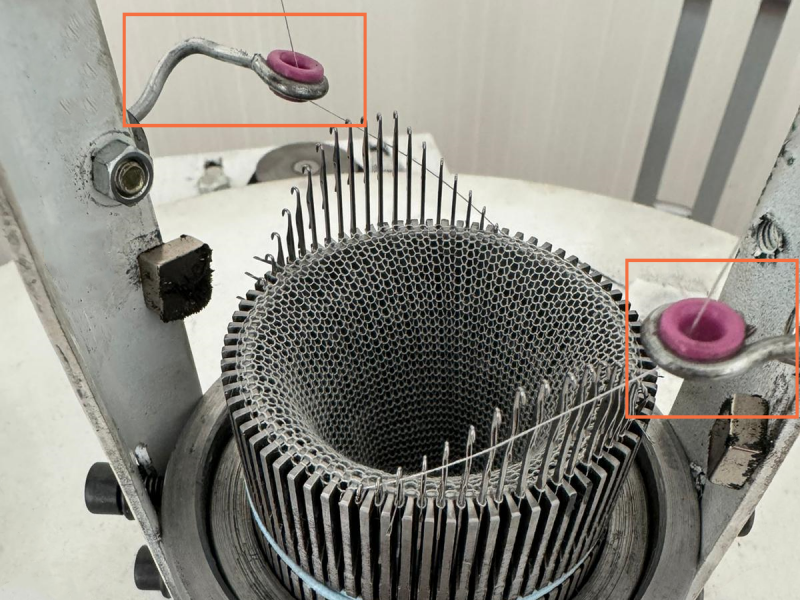

Check that the yarn holders with the red square makred in the photo fo the yanr inlet is in the right place to ensure that the yarn is guided smoothly into the hook of the needle.

You could slightly adjust the position of the yarn controller until the yarn is able to go smoothly into the hook in sequence when head turning.

Needles are among the most crucial components of a rope machine and a primary cause of skipped stitches. Check for bent, broken, or worn needles. Replace any defective needles promptly. Additionally, regular cleaning and lubrication are essential to maintain optimal head performance.

Step 3: Check the Rope Pulling Speed

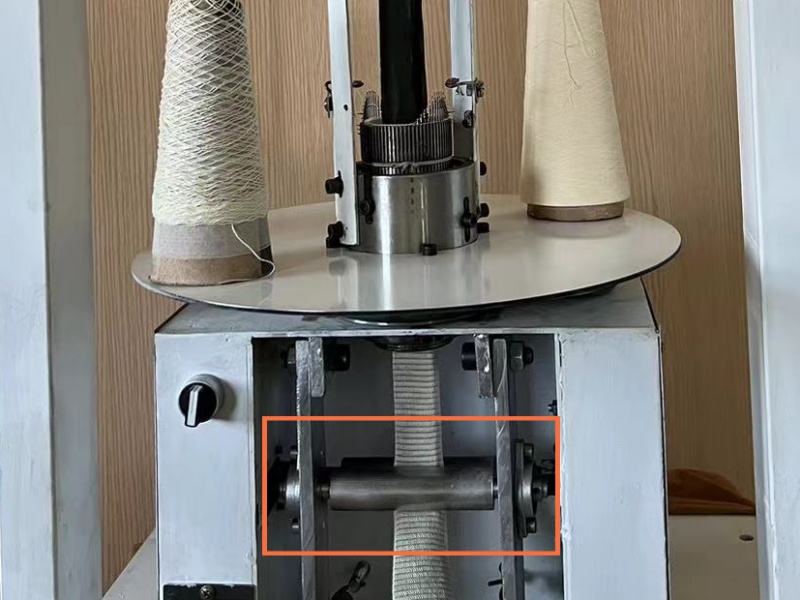

The speed of the rope pulley can also affect whether or not skipped stitches occur. If the speed is too fast or too slow, it can disrupt the smooth knitting process. If the machine was working fine initially but suddenly started producing skipped stitches, check if the pulling speed has changed.

Different materials of yarn head turning knitting into rope and pulling wheel to pull out the rope speed settings are different, the two speeds match well to produce the perfect rope.

If you are new to the operation, you need to do more tests to gain experience.

Inspection Steps:

Observe the rope pulling mechanism in action and check if the speed is consistent.

Examine the belt connected to the pulling mechanism for any looseness or slipping.

Verify that the pulling mechanism is properly positioned.

Adjustment Methods:

If the belt is loose, tighten it appropriately.

Replace the belt if it’s worn out or slipping.

Adjust the position of the pulling mechanism if it’s misaligned.

Conclusion

In conclusion, we hope this comprehensive guide has equipped you with the knowledge and techniques to effectively troubleshoot and resolve skipped stitch issues on your rope machine. Remember, consistent attention to detail, preventive maintenance, and proper operation practices are key to achieving smooth, high-quality rope knitting results.

If you encounter any further challenges or have questions related to your rope machine, MIIYOUNG is always here to assist you. Our team of experienced technicians and knowledgeable representatives is dedicated to providing prompt and effective support, ensuring your rope machine continues to operate at its peak performance.