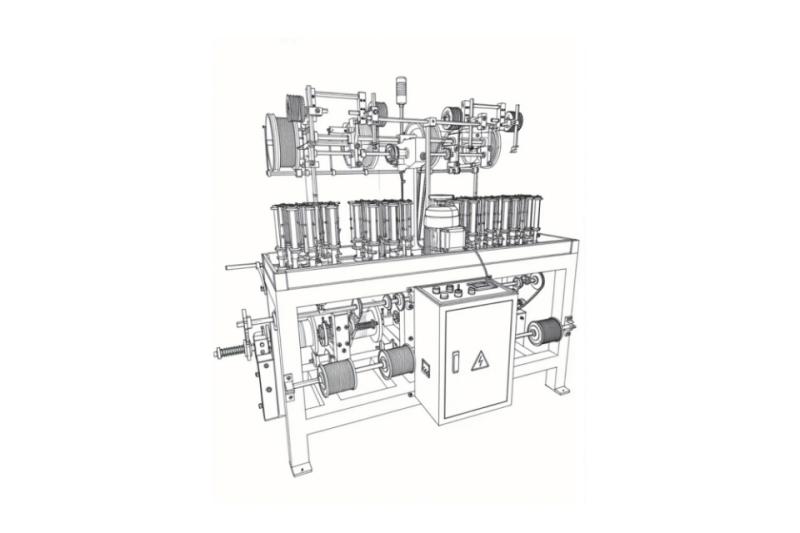

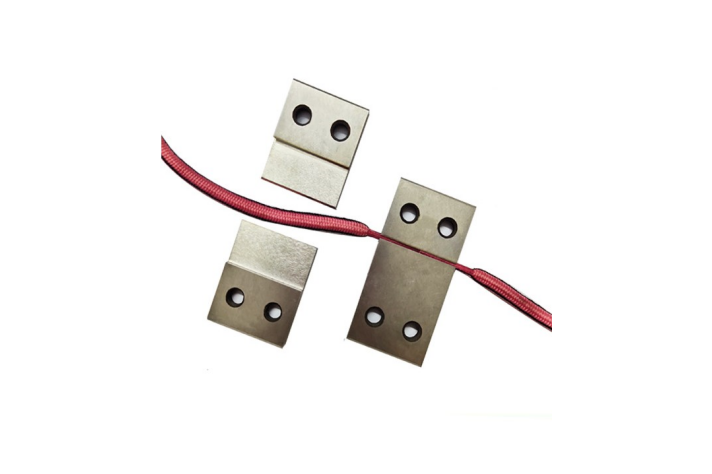

A tipping machine is a specialized machine used to process the ends of cords and laces. It tightly wraps acetate film around the ends of gift wrapping cords, garment tapes, or shoelaces, making the ends sturdy, durable, and aesthetically pleasing.

Types of Tipping Machines:

Tipping machines are mainly divided into two types: semi-automatic tipping machines and fully automatic tipping machines.

- Semi-automatic Tipping Machines:

- Semi-automatic tipping machines require manual operation in conjunction with the machine. Workers need to place the cord into the machine and control it to wrap and cut.

- Advantages:

- Lower machine cost.

- Cord length can be adjusted as needed.

- Disadvantages:

- One worker is required per machine.

- Production speed is affected by the worker’s operation speed.

- Fully Automatic Tipping Machines:

- Fully automatic tipping machines can automatically complete cord wrapping, cutting, and end processing after parameters are set.

- Advantages:

- High production efficiency, one person can manage multiple machines simultaneously.

- Reduced labor costs.

- Disadvantages:

- Higher machine cost.

Applications of Tipping Machines:

Tipping machines are widely used in gift packaging, clothing, footwear, and other industries. They can improve production efficiency, ensure product quality, and make cord ends more beautiful, durable and useful.

Expanding Application Areas:

- Beyond gift wrapping, clothing, and footwear, tipping machines are also widely used in industries like bags, toys, and electronics. For example, some electronic product connection cables use tipping machines to prevent wire ends from fraying.

- In industrial settings, specialized ropes or cables are often reinforced with tipping machines to improve their wear resistance and lifespan.

Technological Advancements in Tipping Machines:

- With ongoing advancements in automation, fully automatic tipping machines are becoming increasingly intelligent. For instance, some advanced models are equipped with visual inspection systems that automatically detect cord quality and reject defective products.

- Newer tipping machines are also using a wider variety of materials. In addition to traditional acetate film, materials like heat-shrink film are also being used, providing more product options.

Factors to Consider When Choosing a Tipping Machine:

- Production Scale: Choose a semi-automatic machine for smaller production volumes and a fully automatic machine for larger volumes.

- Product Type: Select a machine suitable for the cord’s material, size, and shape.

- Budget: Choose a tipping machine that offers good value for your budget.

- Machine Stability and After-Sales Service: Ensure that the machine that is purchased is from a reliable company, that can provide good support.

If you still have any questions about heading machines, feel free to share them with us. We will do our best to assist you.